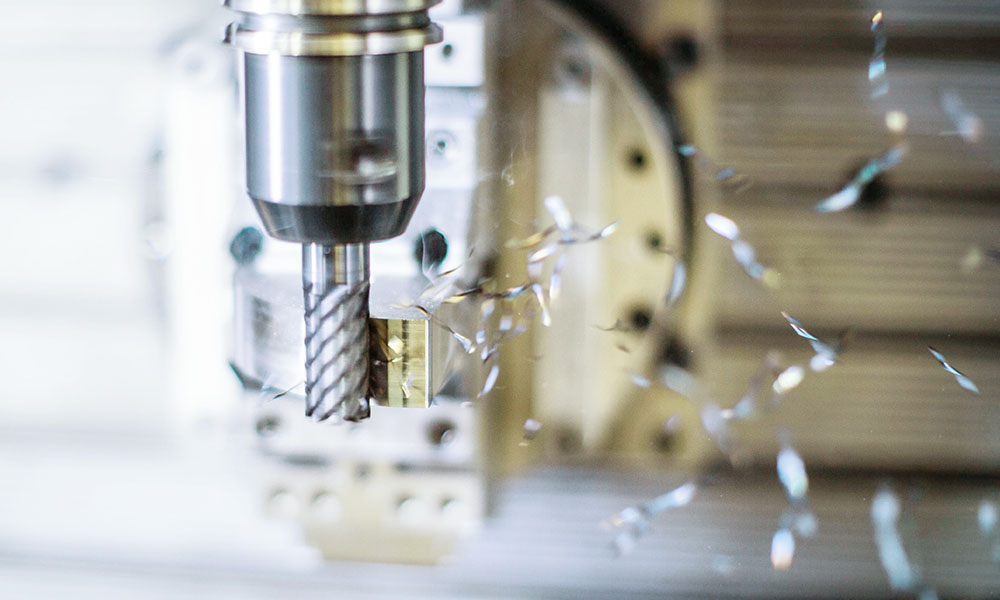

ARMBRUSTER is your experienced contract manufacturer in CNC milling – a company that sets standards for precision and reliable production of milled parts and other components.

As a family-run business, we rely on modern, automated CNC milling centres and efficient processes that help you achieve your production goals in a cost-effective and timely manner. ARMBRUSTER stands for successful, dependable collaboration in contract manufacturing – whether you require individual parts, small batches, or large-scale series production.

With over 30 years of experience in CNC production, ARMBRUSTER stands for precision and quality in milling operations. Using state-of-the-art CNC technology and a deep understanding of customer-specific requirements, we provide tailored solutions that meet the highest standards.

From individual milled parts to complete assemblies. We handle every stage – from raw material to fully assembled components.

For a wide range of materials. Including stainless steel, steel, plastics, and special alloys.

From 3D free-form surfaces to 5-axis simultaneous milling. We manufacture even the most demanding component geometries with precision.

With measuring probes, laser tool measurement, and integrated inspection stations. We ensure consistently high quality across all production stages.

Advanced CAM systems for cost-optimized part production. Our automation enables efficient, precise, and economical manufacturing.

Our machine park sets the benchmark: Equipped with state-of-the-art CNC milling machines and fully automated machining centres, we offer flexible and cost-efficient contract manufacturing that meets the highest quality standards.

With next-generation 5-axis milling centres – including models from Fehlmann and DMG Mori featuring precise Heidenhain controls – we ensure reliable and high-performance production. Extensive tool capacities, linear drives, and automation enable precise and stable processes that are ideally suited for complex components, prototypes, single parts, and series production alike.

Our automated machining centres enable unmanned 24/7 production – ensuring shorter delivery times and optimized cost efficiency. This allows us to machine demanding geometries, such as form- and positional-tolerance cubes, 3D free-form surfaces, or complex 5-axis simultaneous components, in a single operation.

Our machine park is versatile and adaptable, allowing us to efficiently process a wide range of materials – from steel, stainless steel, and aluminium to titanium and plastics. Our advanced CAD and CAM systems support high-performance machining strategies that ensure maximum efficiency and reduced manufacturing costs. Thanks to the precise coordination of X-, Y-, and 5-axis simultaneous movements, we provide exceptional dimensional accuracy and quality in every workpiece.

We offer tailored solutions for your components, regardless of order size – whether for single parts, prototypes, or series production.

There’s no need to invest in expensive machinery or additional personnel. ARMBRUSTER handles the entire manufacturing process, allowing you to focus on your core competencies.

Our automation and efficient processes ensure rapid turnaround and on-time delivery of your orders.

Our comprehensive quality control and the use of modern CNC machines ensure that all components are manufactured with the highest precision and tight tolerances.

Our automated production processes ensure efficient and seamless manufacturing that delivers top quality while optimizing costs.

With over 30 years of experience and a highly qualified team, we offer in-depth expertise and guarantee excellent results in every stage of the manufacturing process.

Our manufacturing is flexible, allowing us to respond quickly to changes and implement your requirements with precision at any time.

We offer a comprehensive selection of materials – from metals such as steel and aluminium to plastics – to ensure optimal manufacturing of your components.

With a standardized platform, we ensure system reliability, fast employee onboarding, and straightforward maintenance of our machines and equipment.

You have a dedicated contact who guides you through the entire process to implement your requirements efficiently and precisely.

Whether precision components for industrial use or custom implants for medical technology – we combine technical excellence with innovative solutions. With dedication and the utmost care, we create products that perform reliably in the most demanding situations.

| Industry: | Medical Technology |

| Application: | Alignment and adjustment of knee implants |

| Process: | CNC Milling |

| Industry: | Medical Technology |

| Application: | Preparation of the femur for the femoral-side implant |

| Process: | CNC Milling |

| Manufactured for: | Smith & Nephew GmbH |

Do you have an inquiry or would you like to request a quote for contract manufacturing? Please use our inquiry form, where you can upload your order data and files (e.g. drawing) quickly and easily.

With cutting-edge manufacturing technology and our expertise, we deliver custom-made products that impress with quality and reliability – always one step ahead.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.

ARMBRUSTER stands for precision, reliability, and a strong focus on customer satisfaction – qualities that make us your ideal partner for CNC milling, from single-part production to large-scale series.

With our state-of-the-art machining centre and flexible manufacturing capacities, we are able to produce even the most demanding components with the highest accuracy. Our automated 5-axis milling centres allow us to manufacture your milled parts not only precisely and quickly, but also cost-effectively. Thanks to our unmanned 24/7 production, we are able to deliver on time – even for complex special components and high-volume orders.

What truly sets us apart is our personalized approach. We take the time to understand your requirements in detail to offer tailored solutions that precisely meet your needs. From initial enquiry to final delivery, we support you with technical expertise and commitment to ensure the success of your project. Our goal is not only to deliver high-quality components, but also to foster long-term partnerships built on trust, transparency, and mutual success.

Still not convinced? Feel free to get in touch – we’re happy to support you personally with your questions and requirements.

As a CNC milling contract manufacturer, ARMBRUSTER offers a wide selection of materials to ensure your components are perfectly suited to their application. We machine:

With our extensive experience and technically advanced machine park, we are able to machine any material with precision and reliability – whether for single parts, prototypes, or series production. You can rely on us to manufacture your components exactly to your specifications.

Absolutely! At ARMBRUSTER, an order doesn’t have to be large to be important. That’s why we specialize in small batch CNC milling as well. With flexible capacities and state-of-the-art machinery, we manufacture low quantities with the same precision and dedication as we do for large-scale production.

Even in small batch production, we maintain consistently high quality – because your requirements define our standards.

At ARMBRUSTER, quality is no coincidence – it’s the result of well-designed processes and state-of-the-art technology. To guarantee the highest precision in CNC contract milling, we use advanced measuring probes and conduct regular quality inspections throughout the production process.

Every component is thoroughly checked to ensure it meets your exact specifications before leaving our facility. We understand that your trust in our quality is the foundation of our partnership – and we do everything to make sure you experience that trust in every part we deliver.

Yes – and with true passion for precision! Thanks to our 5-axis simultaneous milling centres, we can machine even the most complex geometries and freeform surfaces with millimetre-level accuracy. Whether it’s form- and position-toleranced cubes, 3D freeform surfaces, or intricate simultaneous geometries – our advanced CAD and CAM systems reliably translate your design data into finished components.

Our entire team is committed to realising your complex parts exactly as specified – down to the finest detail.

Requesting a quotation from ARMBRUSTER is quick and straightforward. Simply use our enquiry form to send us all relevant information and data about your project. Our team will get back to you as soon as possible to discuss the details and provide you with a customized offer.

Alternatively, you can of course contact us by phone or email – our team is always available to answer your questions and discuss your requirements.

Our expertise in contract manufacturing goes far beyond CNC milling – we offer a wide range of machining capabilities to meet your needs comprehensively:

This broad service portfolio makes ARMBRUSTER a fully equipped contract manufacturer ready to meet your requirements in every aspect. We believe in offering you all essential manufacturing processes from a single source – to support your projects as efficiently and effectively as possible.