Additive manufacturing is a key complement to our proven machining processes and opens up new possibilities in the production of complex components. Both metal and plastic 3D printing technologies enable the layer-by-layer creation of parts – efficiently, precisely, and resource-consciously.

Whether in medical technology, industrial applications, or the production of prototypes and serial components: our expertise in additive manufacturing helps you bring innovative products to life and manufacture them cost-effectively. With state-of-the-art technology and a holistic approach, we are your reliable partner for customized manufacturing solutions.

With our expertise and state-of-the-art technologies, we set new standards in additive manufacturing. We offer:

From the printed state through machining to surface treatment, we cover the entire manufacturing process – all from a single source.

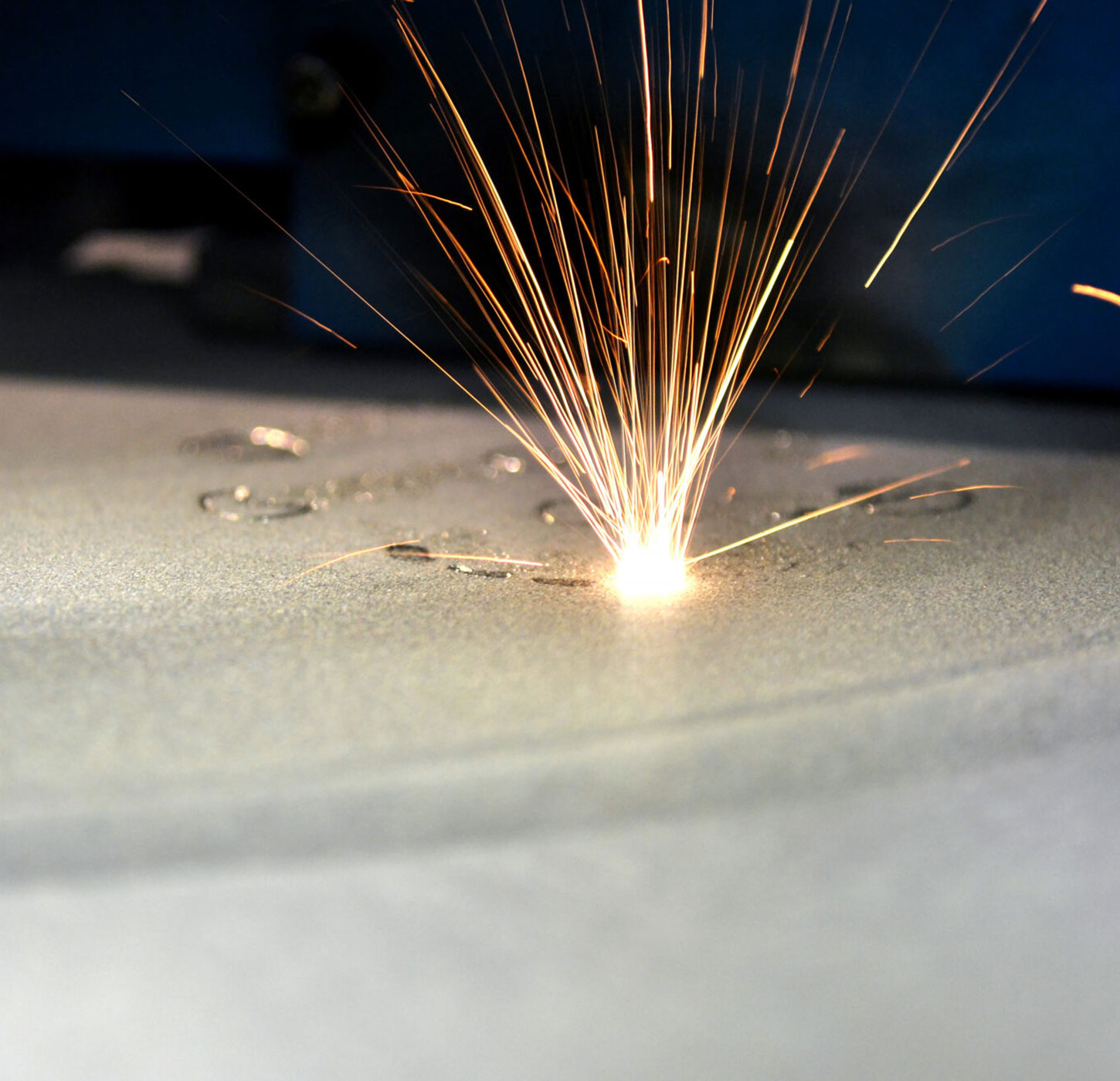

Using SLM technology (Selective Laser Melting) with our metal 3D printer, we realize even the most complex designs with the highest accuracy – ideal for delicate geometries and demanding functional parts. Additionally, we offer plastic 3D printing processes that provide flexible and precise solutions for sophisticated plastic components.

We use the stainless steel grade 1.4542 (17-4 PH / AISI 630), which is highly versatile and suitable for a wide range of applications across various industries.

Thanks to advanced printing technology, we ensure not only high production speed but also consistent quality at every stage of the manufacturing process.

Our process is tailored to meet industrial requirements – stable, reliable, and precise from design to the finished product.

We manufacture shapes that are difficult or impossible to produce using conventional machining methods.

By using additive instead of subtractive manufacturing technologies, material is built up precisely rather than removed. This not only conserves raw materials but also reduces processing time and makes production more cost-efficient.

Additive manufacturing replaces expensive cast components and also offers shorter production times.

Multi-part assemblies can be consolidated into a single component, saving both time and costs.

Particularly cost-effective for low volumes and prototypes.

Our functional prototypes are ready for use in the shortest possible time – ideal for product development.

Whether precision components for industrial use or custom implants for medical technology – we combine technical excellence with innovative solutions. With dedication and the utmost care, we create products that perform reliably in the most demanding situations.

| Industry: | Medical Technology |

| Application: | Trial implant for determining implant size |

| Processing: | Additive Manufacturing |

| Industry: | Medical Technology |

| Application: | Titanium implant (wedge) for foot bone fusion |

| Processing: | Additive Manufacturing |

| Industry: | Medical Technology |

| Application: | For stabilization and reconstruction of the foot bone |

| Processing: | Additive Manufacturing |

Do you have an inquiry or would you like to request a quote for contract manufacturing? Please use our inquiry form, where you can upload your order data and files (e.g. drawing) quickly and easily.

With cutting-edge manufacturing technology and our expertise, we deliver custom-made products that impress with quality and reliability – always one step ahead.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.