Home Services Full-Service Provider CNC Contract Manufacturer

Precision, efficiency, and flexibility – these are the standards we apply to every part we manufacture at ARMBRUSTER. As a trusted CNC contract manufacturer, we deliver complex components and assemblies that meet the highest industry requirements. From prototypes to large-scale production, we provide cost-efficient solutions based on advanced manufacturing technologies and outstanding engineering expertise. Our work focuses on ultra-precise machining and exceptional surface quality, ensuring your components meet the strictest performance and quality standards.

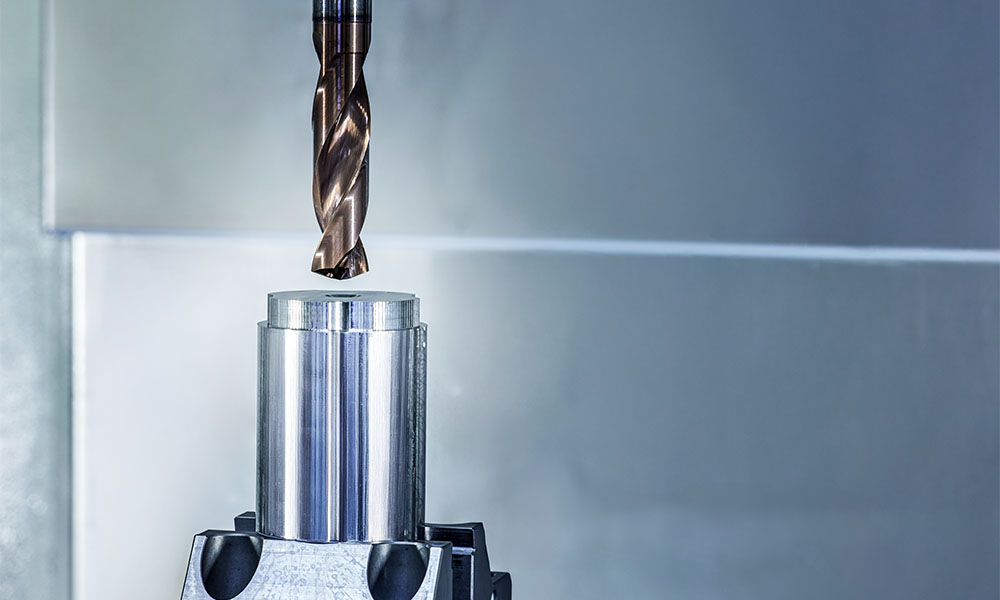

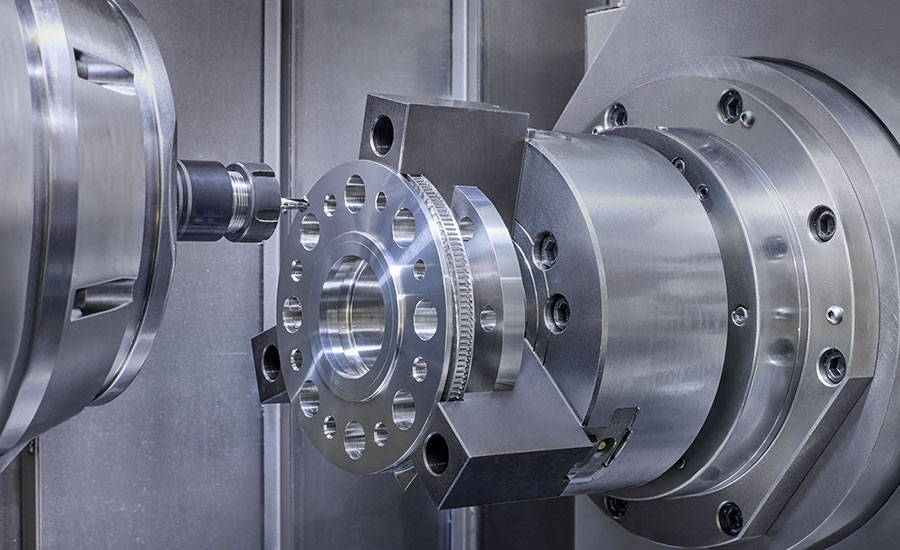

With over 30 years of experience in CNC contract manufacturing, ARMBRUSTER is your reliable partner for high-precision components. Our core expertise lies in machining stainless steel, high-alloy steels, titanium, aluminum, and engineering plastics. Utilizing state-of-the-art production systems and advanced techniques such as CNC milling, CNC turning, sinker and wire EDM, and additive manufacturing, we deliver efficient and accurate results – every time.

From your initial idea and technical drawings to the finished part and on-time delivery, we support you throughout the entire process. Whether you need a prototype, small batch, or full-scale production, our skilled team ensures precision and consistency at every step. With tailored consulting and professional project support, we help you develop the optimal solution for your specific application.

Our state-of-the-art machinery is specifically designed to meet the demands of complex and high-precision manufacturing processes:

For complex turned and milled parts with the highest precision requirements.

CAD-assisted machining of intricate geometries and multi-axis components.

For the precise machining of delicate components and challenging materials.

Fast and cost-efficient production of prototypes and functional parts using metal and plastic 3D printing.

With our versatile production capabilities, we can manufacture components in a wide range of diameters, dimensions, and materials. In addition, we offer extensive surface finishing options either in-house or through our trusted partner network.

We offer tailored solutions for your components, regardless of order size – whether for single parts, prototypes, or series production.

There’s no need to invest in expensive machinery or additional personnel. ARMBRUSTER handles the entire manufacturing process, allowing you to focus on your core competencies.

Our automation and efficient processes ensure rapid turnaround and on-time delivery of your orders.

Our comprehensive quality control and the use of modern CNC machines ensure that all components are manufactured with the highest precision and tight tolerances.

Our automated production processes ensure efficient and seamless manufacturing that delivers top quality while optimizing costs.

With over 30 years of experience and a highly qualified team, we offer in-depth expertise and guarantee excellent results in every stage of the manufacturing process.

Our manufacturing is flexible, allowing us to respond quickly to changes and implement your requirements with precision at any time.

We offer a comprehensive selection of materials – from metals such as steel and aluminium to plastics – to ensure optimal manufacturing of your components.

With a standardized platform, we ensure system reliability, fast employee onboarding, and straightforward maintenance of our machines and equipment.

You have a dedicated contact who guides you through the entire process to implement your requirements efficiently and precisely.

In precision engineering, we focus on the finest tolerances and exacting manufacturing to deliver products that perform reliably even in the most demanding applications.

Do you have an inquiry or would you like to request a quote for contract manufacturing? Please use our inquiry form, where you can upload your order data and files (e.g. drawing) quickly and easily.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.

With state-of-the-art manufacturing technologies and the highest quality standards, we produce components not only as a contract manufacturer for medical devices but also for a wide range of industries – precise, reliable and certified.

A CNC contract manufacturer specializes in the precise production of components and assemblies using CNC-controlled machinery. Acting on behalf of other companies, the manufacturer provides expertise, flexibility, and access to a modern, high-performance machine park. By outsourcing CNC contract manufacturing, businesses can save time, resources and costs, while focusing on their core competencies.

CNC contract manufacturing is essential across various industries, including medical technology, automotive, mechanical engineering, toolmaking, and electrical engineering. Thanks to the precision and versatility of CNC technology, components can be produced for a wide range of applications – from prototypes to full-scale series production.

ARMBRUSTER delivers the highest precision, an extensive machine park, and a skilled team. We provide cost-effective solutions, reliable delivery times, and personalized support – from development through to delivery. Our comprehensive additional services, such as surface finishing, assembly, and quality assurance, make us a strong and dependable partner for your projects.

At ARMBRUSTER, we process a wide range of materials including stainless steel, titanium, aluminium, and high-performance plastics. Our advanced machining technology enables us to handle difficult-to-machine materials as well as lightweight and delicate components with ease and precision.

Yes, we manufacture both small and medium batch sizes with the highest level of precision. Our flexible production planning allows for cost-effective manufacturing in various quantities – always with a focus on quality and on-time delivery.

Our CNC contract manufacturing services include milling, turning, wire EDM, and sinker EDM. These are complemented by additional processes such as grinding, welding, and surface treatments. Together, these capabilities ensure that every part is manufactured precisely and according to your specifications.

Our quality assurance is based on the latest inspection technologies and a transparent production process. Every part undergoes rigorous quality checks to meet the highest standards. Additionally, we document all manufacturing steps to ensure full traceability of each component.