At ARMBRUSTER, every product we manufacture sets a benchmark for quality. Our goal is not simply to deliver parts, but to provide solutions that impress through outstanding quality and reliably meet your requirements over the long term. This high standard is ensured by our efficient quality management system and rigorous quality assurance processes.

Our quality assurance begins as early as the product concept phase. Even during prototyping, we evaluate your products for functional suitability and economic feasibility. Critical characteristics are identified and documented in inspection plans. Quality is continuously monitored through in-process-inspections, enabling early optimization and error prevention.

Our climate-controlled inspection rooms provide ideal conditions for precise measurements. In addition to calibrated hand-held measuring instruments, we use advanced systems such as tactile 3D coordinate measuring machines with rotary swivel heads, optical measuring technology, and surface roughness testers.

Beyond final inspection, we rely on standardized testing methods including measurement reports, initial sample inspection reports, AQL-based random sampling, and 100% inspections to ensure that every product meets the highest quality standards.

For us, quality management is more than just a concept – it is a lived philosophy throughout every area of our company. Our system meets all relevant standards and is designed to be both practical and clearly structured. Processes are qualified, validated, and tailored to specific product classes and industries.

We ensure complete traceability across all production steps. A CAQ system centralizes all quality-relevant data, enables seamless documentation, and manages both measurement data exchange and complaint handling. This guarantees transparency, fast response times, and continuous improvement.

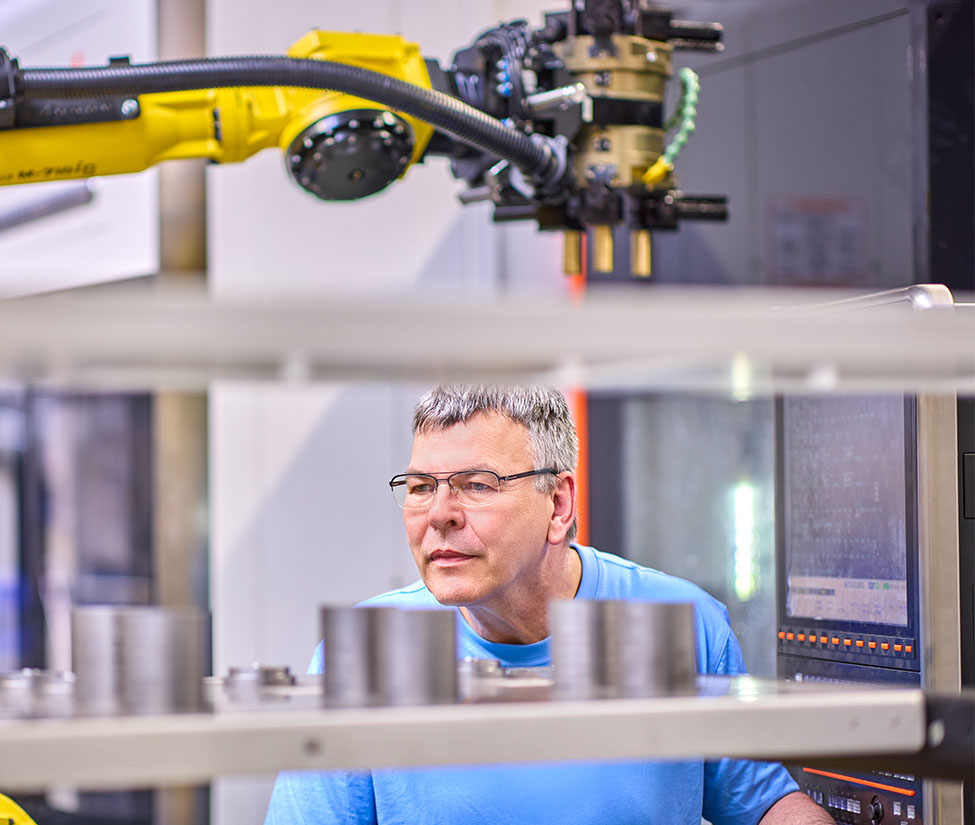

Our leadership structure ensures swift, standardized decision-making. In-house production, automation, and qualified employees secure stable processes. Regular internal audits improve workflows and reinforce quality awareness. We also handle external audits by partners, authorities, and notified bodies with professionalism – ensuring consistent compliance with the highest international standards.

PDF | 0.2 MB

PDF | 0.2 MB

PDF | 0.2 MB

PDF | 0.2 MB

We are certified according to international standards ISO 9001:2015 and ISO 13485:2021.

These certificates confirm that we meet all relevant quality and safety requirements and ensure that our processes and products operate at the highest level.

As an internationally active partner in the field of medical technology, we meet the highest regulatory requirements – both in Europe and on the US market.

Our company is registered with the U.S. Food and Drug Administration (FDA) and complies with the requirements of FDA 21 CFR Part 820 (“Quality System Regulation”), which governs quality management systems for medical device manufacturers in the United States.

FDA Registration Number: 3013194153

Owner Operator Number: 10054478

With this registration, we ensure that our processes, documentation, and manufacturing standards meet all legal requirements set by the FDA. It reflects our commitment to quality, safety, and transparency – and forms the foundation for compliant and market-ready supply to the U.S. medical device sector.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.

With cutting-edge manufacturing technology and our expertise, we deliver custom-made products that impress with quality and reliability – always one step ahead.