At ARMBRUSTER, we have stood for passion, precision, and reliability in component machining for over three decades. The combination of our expertise, skilled team, and state-of-the-art machine park makes us your trusted partner for sinker and wire EDM subcontracting.

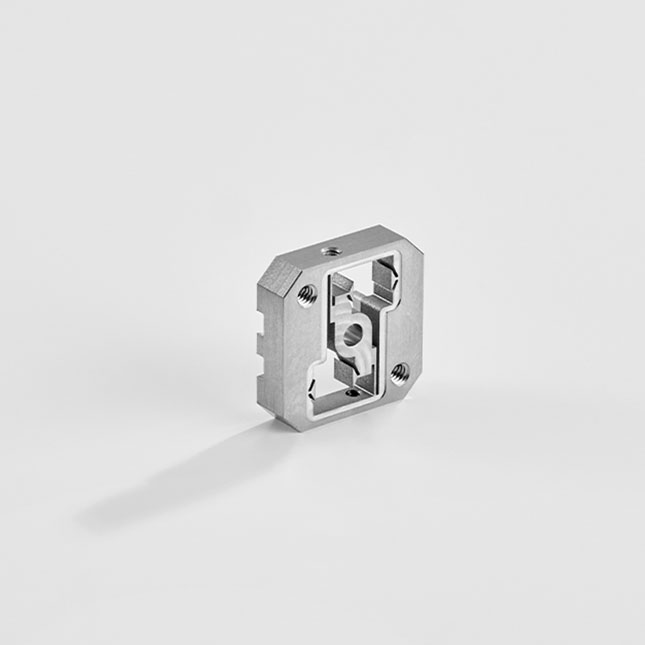

Whether intricate EDM parts, complex geometries, or custom tooling – we manufacture your components with the highest precision, combining advanced technology with a deep understanding of your individual requirements. Our goal is not just to produce parts, but to deliver solutions that fulfil your technical and functional needs perfectly.

Wire EDM and sinker EDM are among the most advanced manufacturing methods in subcontracting – and they are key areas of expertise at ARMBRUSTER.

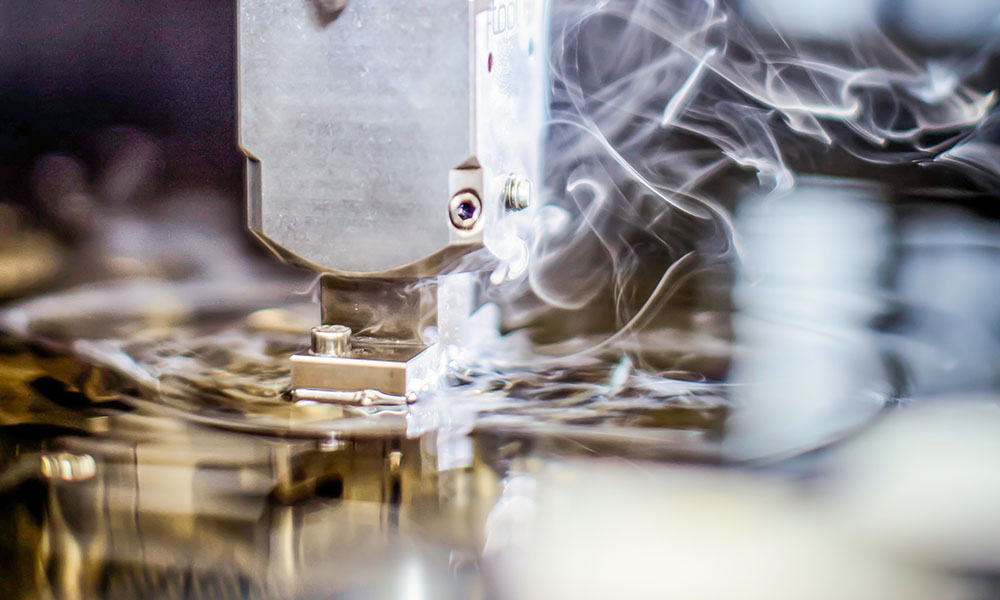

In Wire EDM, a thin wire is used as an electrode and guided precisely through the workpiece. This method enables us to produce highly accurate contours, delicate geometries, and even extremely complex components – ideal for toolmaking, mechanical engineering, and medical technology.

Sinker EDM uses a shaped electrode that sinks into the workpiece and removes material through spark erosion. This technique is especially suited for deep cavities, complex shapes, and demanding tooling applications.

At ARMBRUSTER, we combine both technologies – wire and sinker EDM – to offer you a comprehensive solution tailored to your requirements. Thanks to our expertise and cutting-edge machine park, we can implement individual customer specifications with precision – from single parts and prototypes to full series production.

We focus on quality, precision, and personal consultation to ensure the success of your project. We don’t just manufacture products – we deliver quality you can rely on.

The combination of sinker and wire EDM allows us to perfectly align with upstream processes, enabling even more efficient and faster production of your components. From complex geometries to demanding EDM parts – our CNC technology and expertise are your advantage.

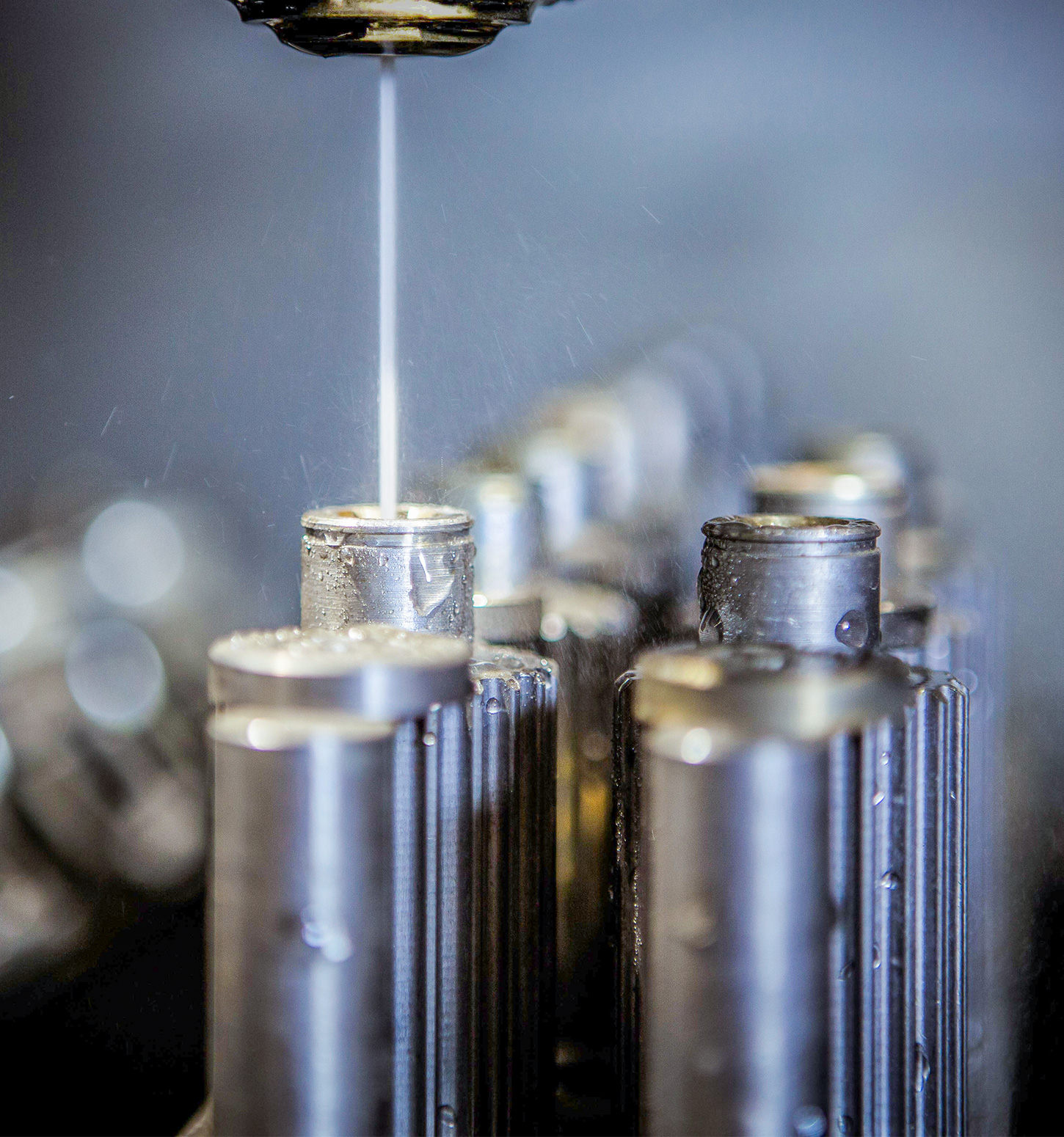

For Wire EDM, we use state-of-the-art machines from Agie GF, equipped with palletising systems. With tilting units and specially developed fixtures, we can machine multiple angled contours in a single setup – ensuring maximum precision and efficiency.

In Sinker EDM, we rely on Sodick machines. Using a zero-point clamping system for both workpieces and electrodes, we enable external presetting on the coordinate measuring machine. The measurement data is transmitted directly to the EDM machine – speeding up the process and ensuring outstanding accuracy.

We offer tailored solutions for your components, regardless of order size – whether for single parts, prototypes, or series production.

There’s no need to invest in expensive machinery or additional personnel. ARMBRUSTER handles the entire manufacturing process, allowing you to focus on your core competencies.

Our automation and efficient processes ensure rapid turnaround and on-time delivery of your orders.

Our comprehensive quality control and the use of modern CNC machines ensure that all components are manufactured with the highest precision and tight tolerances.

Our automated production processes ensure efficient and seamless manufacturing that delivers top quality while optimizing costs.

With over 30 years of experience and a highly qualified team, we offer in-depth expertise and guarantee excellent results in every stage of the manufacturing process.

Our manufacturing is flexible, allowing us to respond quickly to changes and implement your requirements with precision at any time.

We offer a comprehensive selection of materials – from metals such as steel and aluminium to plastics – to ensure optimal manufacturing of your components.

With a standardized platform, we ensure system reliability, fast employee onboarding, and straightforward maintenance of our machines and equipment.

You have a dedicated contact who guides you through the entire process to implement your requirements efficiently and precisely.

Whether precision components for industrial use or custom implants for medical technology – we combine technical excellence with innovative solutions. With dedication and the utmost care, we create products that perform reliably in the most demanding situations.

| Industry: | Medical Technology |

| Application: | Preparation of the femur for the femoral-side implant |

| Process: | Wire EDM |

| Manufactured for: | Smith & Nephew GmbH |

| Industry: | Metrology |

| Application: | For miniature positioners in vacuum environments |

| Process: | Wire EDM |

Do you have an inquiry or would you like to request a quote for contract manufacturing? Please use our inquiry form, where you can upload your order data and files (e.g. drawing) quickly and easily.

With cutting-edge manufacturing technology and our expertise, we deliver custom-made products that impress with quality and reliability – always one step ahead.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.

Wire EDM (Electrical Discharge Machining), also known as wire erosion or wire cutting, is a high-precision manufacturing process in which a thin, electrically conductive wire removes material from a workpiece through spark erosion. This method is ideal for producing complex geometries, delicate components, and precision tools.

At ARMBRUSTER, we use wire EDM technology to meet demanding requirements in toolmaking, medical technology, and mechanical engineering.

Sinker EDM (Electrical Discharge Machining) is a precise manufacturing process based on spark erosion. A specially shaped electrode is used to remove material from a conductive workpiece through controlled electrical discharges. The electrode, shaped as the negative form of the desired part, is lowered into the workpiece. A small gap between the electrode and the workpiece allows targeted spark erosion to remove the material.

This process is especially suited for manufacturing tools, moulds, and complex components that are difficult or impossible to produce using conventional machining methods.

Wire EDM and sinker EDM are both electrical discharge machining (EDM) processes, but they differ in how they work and where they are applied.

Wire EDM uses a continuous, electrically conductive wire as an electrode to cut through the workpiece and create precise contours. In contrast, sinker EDM uses a solid, pre-shaped electrode that forms cavities in the workpiece by spark erosion.

At ARMBRUSTER, we operate CNC-controlled wire EDM machines with travel ranges up to X800, Y600, Z510 mm. Wire EDM is especially suitable for:

Sinker EDM is used when complex three-dimensional shapes or deep cavities are needed. A specially shaped electrode is lowered into the workpiece, and controlled spark discharges remove material. Its advantages include:

At ARMBRUSTER, we master both EDM technologies and combine them to deliver precise, custom solutions tailored to your product requirements.

Outsourcing wire EDM to a specialised contract manufacturer offers many advantages – especially if your business lacks the necessary equipment, capacity, or expertise.

1. Cost Savings

Investing in state-of-the-art wire EDM machines is costly. Maintenance, operator training, and operating expenses add further overhead. By outsourcing to an experienced contract manufacturer like ARMBRUSTER, you avoid these high costs and can focus on your core competencies.

2. Access to Advanced Technology

As a specialised partner, ARMBRUSTER operates a high-end EDM machine park equipped for complex and precise workpieces. Our automated wire EDM systems include palletising technology and tilting devices that allow intricate geometries to be machined in a single setup – with maximum accuracy.

3. Flexibility and Capacity

Wire EDM subcontracting gives you the freedom to handle projects of any size – from single parts to series production – without tying up your own resources. This is especially useful when additional capacity is needed at short notice.

4. Expertise and Quality

With over 30 years of experience in precision manufacturing, ARMBRUSTER delivers parts to the highest standards. Our experts work with care and precision, supported by comprehensive quality control and CAD-assisted production methods. Only perfectly machined parts leave our facility.

5. Efficiency and Time Savings

By combining wire EDM with complementary processes like sinker EDM, milling or turn-mill operations, we ensure seamless integration in your production chain. This leads to faster turnaround times and improved overall efficiency – giving you a competitive edge.

We operate advanced wire EDM machines from Agie GF, equipped with palletising systems and integrated tilting units. These technologies enable us to perform even the most demanding machining operations with high precision and efficiency. Intelligent automation ensures consistently high quality and short lead times.

In wire EDM contract manufacturing, we process a wide range of materials, including:

Thanks to our expertise and modern equipment, we guarantee precise and reliable machining – regardless of the material.

Our machine park is designed for flexibility, allowing us to manufacture single parts, prototypes, and full-scale series. Thanks to automated processes and high production capacity, we can handle even large and complex projects on schedule and with consistently high quality.

With travel ranges of X800, Y600, and Z510 mm, we can machine large and intricate components in a single setup – efficiently and precisely.

Our quality assurance in wire EDM contract manufacturing is based on advanced technology and precise processes. Workpieces and electrodes are preset externally using a zero-point clamping system on our coordinate measuring machine. The measurement data is transferred directly to the wire EDM machines, ensuring maximum accuracy.

Every component undergoes thorough inspection before leaving our facility – so you can rely on consistent precision and dependable results.

By combining wire EDM and sinker EDM, we can flexibly respond to a wide range of manufacturing requirements. Wire EDM is ideal for fine, delicate geometries, while sinker EDM excels in producing deep and complex shapes. This synergy enables us to deliver custom solutions for diverse components – while also optimising production costs and process efficiency.

With over 30 years of experience, a state-of-the-art machine park, and a skilled team, ARMBRUSTER stands for precision, quality, and reliability. As a family-run company, we place great value on personal consultation and close collaboration with our clients.

From initial enquiry to final delivery, we support you as a dependable partner and offer tailored solutions to meet your individual requirements in wire EDM contract manufacturing.

Getting in touch is easy: Simply use our enquiry form, call us directly, or send us an email. Our team is happy to assist you with questions, technical advice, and further information – to help implement your project efficiently and successfully.

Phone: +49 7832 97591-0

E-Mail: info@armbruster.com

In addition to EDM, ARMBRUSTER offers a wide range of manufacturing technologies and services, including: