Cleaning Components is a crucial factor for quality and functionality – especially in demanding industries such as medical technology and precision engineering.

At ARMBRUSTER, we rely on state-of-the-art cleaning technologies and guarantee that your products are cleaned precisely according to your specifications. Whether intermediate cleaning during production or final cleaning for end use – we deliver results that meet the highest standards.

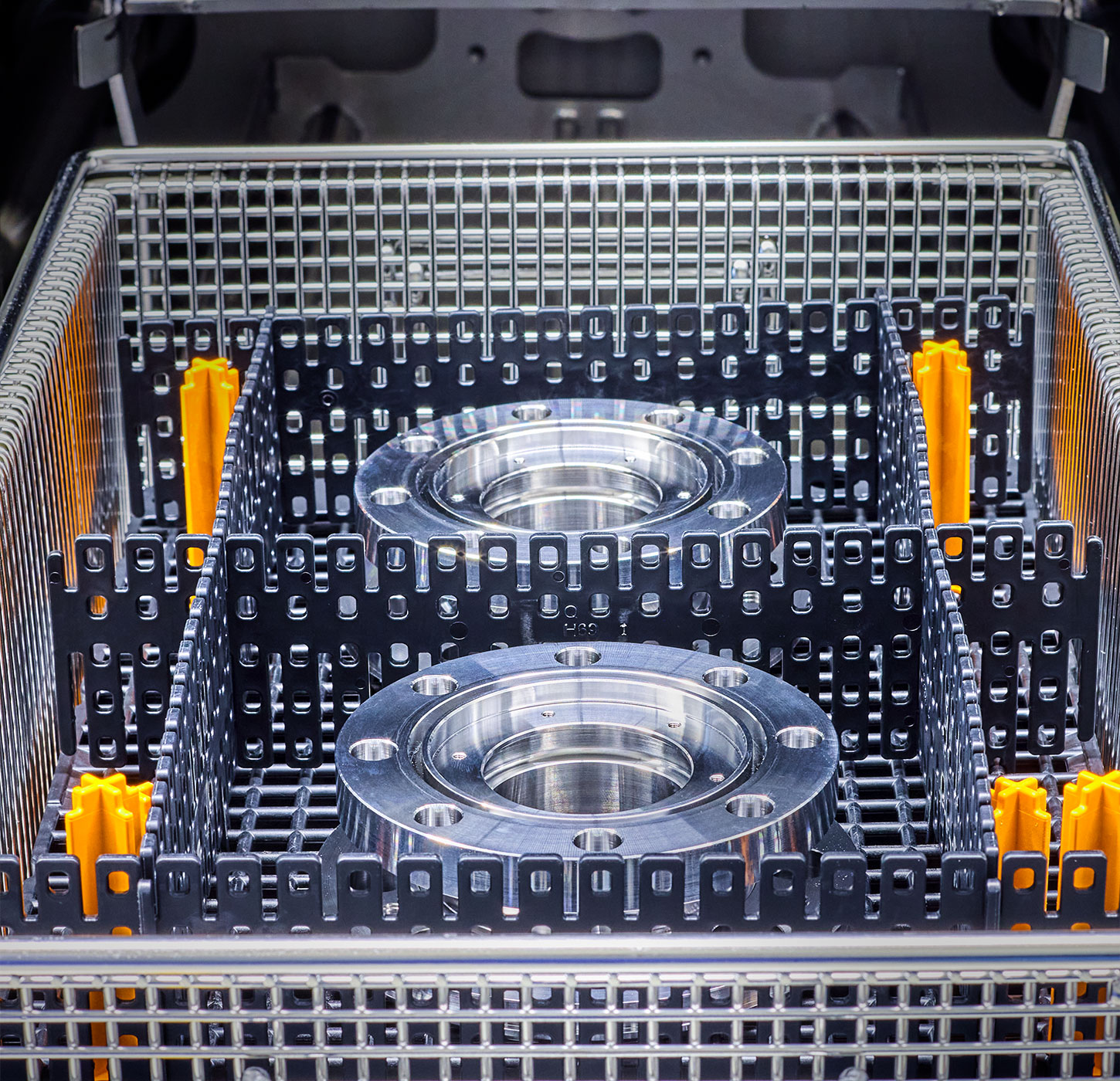

At ARMBRUSTER, parts cleaning is fully integrated into our manufacturing processes and tailored precisely to the requirements of your products. We place particular importance on precision, traceability, and reproducibility. With our extensive know-how in parts cleaning, we guarantee optimal results that meet both functional and visual requirements.

Our state-of-the-art equipment is designed for the precise and reliable cleaning of components:

Our machinery is designed for maximum efficiency and flexibility, enabling us to clean both individual parts and series components reliably and cost-effectively.

Every product is cleaned in accordance with your specifications – precisely and efficiently.

Flexible processes for different stages of production.

Cleaning quality is continuously monitored, internally inspected, and verified by external laboratories.

From alkaline cleaning to rinsing with deionised water – we tailor our processes to meet the specific requirements of your products.

For consistent quality and maximum efficiency.

We guarantee complete traceability of the cleaning processes.

Do you have an inquiry or would you like to request a quote for contract manufacturing? Please use our inquiry form, where you can upload your order data and files (e.g. drawing) quickly and easily.

With cutting-edge manufacturing technology and our expertise, we deliver custom-made products that impress with quality and reliability – always one step ahead.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.