Home Medical Technology

In medical technology, it’s about more than precision – it’s about life itself.

Every procedure, every implant and every surgical instrument plays a role in helping people – relieving pain, restoring mobility and improving quality of life.

As an owner-managed medium-sized company with over 30 years of experience, we take on this responsibility every single day. We understand the specific requirements of the medical technology sector and combine our expertise with state-of-the-art technology to create products that meet the highest quality standards – and that, directly or indirectly, make a real difference to patients’ lives.

Whether for start-ups, SMEs or global corporations – we are a trusted partner who turns ideas into reality. In our core areas, we rank among the leading providers. If needed, we also offer a one-stop service: from development and manufacturing through to the finished product. Thanks to our in-depth understanding of regulatory requirements in medical technology, we can act with flexibility, reliability and efficiency – without ever losing sight of our customers’ individuality and needs. Because ultimately, we all share the same goal: health and quality of life for every patient.

Why ARMBRUSTER is your ideal partner in medical technology

Instruments and implants for the implantation of artificial knee joints – including 4-in-1 and tibial cutting blocks, femur impactors and trial implants.

Additively manufactured trial implant for the precise determination of implant size.

Used to optimize the flexion gap during knee implant procedures, ensuring precise alignment and fit of the prosthesis.

Ensures precise alignment of knee implants during tibial preparation by guiding accurate cutting depths and angles for optimal fit.

Instrument for the precise preparation of the femur for knee implants, enabling accurate multi-angle cuts.

Manufactured for Smith & Nephew GmbH

Instruments and implants for the implantation of artificial hip joints, including rasps, acetabular impactors, and trial implants.

Fully manufactured on turn-mill centres for the preparation of the femur during hip prosthesis implantation.

Innovative implants and instruments for shoulder joint surgery, including compressors, shoulder reamers, metaphyseal components, and glenoids.

A complex stainless steel milled and turned part used for bone preparation to ensure optimal implant seating. Features include cannulation and surface treatment to maintain long-lasting cutting sharpness.

A cobalt-chrome implant manufactured with high precision on mill-turn centres, ensuring exact spherical geometry and a perfect fit.

A fully machined titanium implant with integrated serrations, manufactured as a precision-milled part.

Delicate, cannulated instruments such as pedicle screwdrivers, reduction towers and rod inserters designed for complex spinal procedures.

Stainless steel and titanium instrument featuring cannulated channels and a Torx connection for precise screw placement in spinal surgery.

Precision instrument for spinal procedures, designed to accurately reposition and align vertebrae—especially in the correction of deformities or fractures.

Specialized instruments and implants for treating bone fractures or performing tumor-related surgical procedures.

Carbon-fibre component used to guide the implantation of a nail during femoral fracture procedures, featuring defined markings and detailed assembly and measurement documentation.

Additively manufactured titanium implant designed to stabilize and reconstruct bone structures in the foot.

3D-printed, post-machined and anodized titanium wedge implant used for arthrodesis in foot surgery.

Individually manufactured implants – such as bone replacement implants following tumor surgery – are developed based on CT data and produced with short lead times to meet each patient’s exact anatomical requirements.

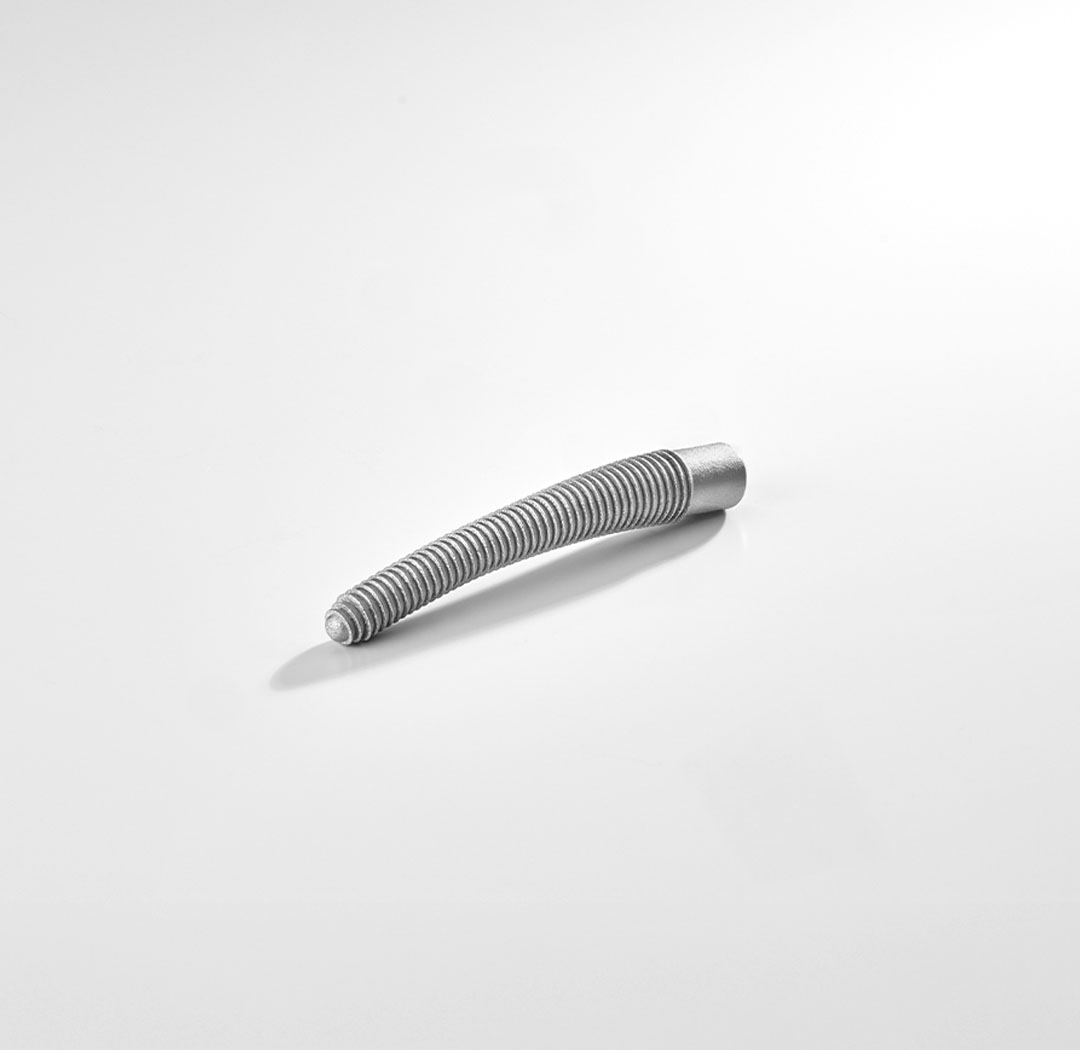

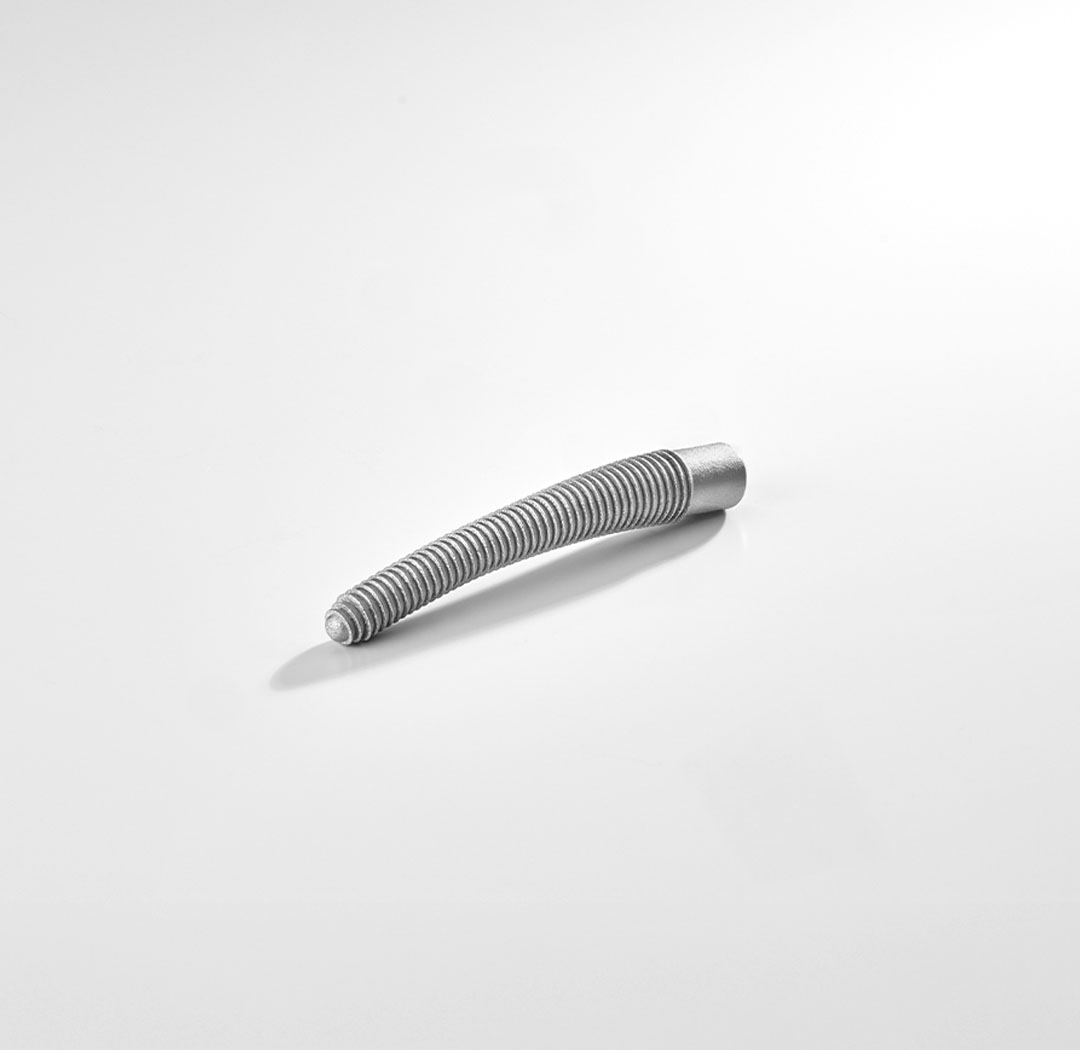

Additively manufactured rasp body made from stainless steel featuring a toothed geometry designed for precise femoral bone preparation.

Patient-specific titanium bone replacement implant for the knee area, featuring a 3D contour surface, deep-hole drilling, groove, and assembled cobalt-chromium bearing bushings.

Instruments and implants for neurosurgery, cardiac surgery and other organ-related procedures.

Thin-walled titanium casing designed to house the electronics of a cardiac pacemaker.

Stainless steel assembly with toothed locking mechanism, used to maintain wound opening during surgical procedures.

Instruments and implants for the implantation of artificial knee joints – including 4-in-1 and tibial cutting blocks, femur impactors and trial implants.

Additively manufactured trial implant for the precise determination of implant size.

Ensures precise alignment of knee implants during tibial preparation by guiding accurate cutting depths and angles for optimal fit.

Instrument for the precise preparation of the femur for knee implants, enabling accurate multi-angle cuts.

Manufactured for Smith & Nephew GmbH

Instruments and implants for the implantation of artificial hip joints, including rasps, acetabular impactors, and trial implants.

Fully manufactured on turn-mill centres for the preparation of the femur during hip prosthesis implantation.

Delicate, cannulated instruments such as pedicle screwdrivers, reduction towers and rod inserters designed for complex spinal procedures.

Stainless steel and titanium instrument featuring cannulated channels and a Torx connection for precise screw placement in spinal surgery.

Precision instrument for spinal procedures, designed to accurately reposition and align vertebrae—especially in the correction of deformities or fractures.

Specialized instruments and implants for treating bone fractures or performing tumor-related surgical procedures.

Carbon-fibre component used to guide the implantation of a nail during femoral fracture procedures, featuring defined markings and detailed assembly and measurement documentation.

Additively manufactured titanium implant designed to stabilize and reconstruct bone structures in the foot.

3D-printed, post-machined and anodized titanium wedge implant used for arthrodesis in foot surgery.

Individually manufactured implants – such as bone replacement implants following tumor surgery – are developed based on CT data and produced with short lead times to meet each patient’s exact anatomical requirements.

Additively manufactured rasp body made from stainless steel featuring a toothed geometry designed for precise femoral bone preparation.

Instruments and implants for neurosurgery, cardiac surgery and other organ-related procedures.

Thin-walled titanium casing designed to house the electronics of a cardiac pacemaker.

Stainless steel assembly with toothed locking mechanism, used to maintain wound opening during surgical procedures.

As a trusted contract manufacturer of medical devices, we offer tailored solutions that meet the highest quality standards. With over 30 years of experience in the medical technology sector and certified production capabilities according to ISO 13485, we support you in the manufacturing of your products – from initial prototypes to full-scale series production.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.

With cutting-edge manufacturing technology and our expertise, we deliver custom-made products that impress with quality and reliability – always one step ahead.

In precision engineering, we focus on the finest tolerances and exacting manufacturing to deliver products that perform reliably even in the most demanding applications.