Home Medical Technology Contract Manufacturer for Implants

As an experienced contract manufacturer for implants, we at ARMBRUSTER are fully aware of the trust our customers place in us – every single day. This trust has been earned through years of close collaboration and an unwavering commitment to quality.

From patient-specific implants in quantities of just one to series production with strategic annual volumes in the thousands, ARMBRUSTER is your reliable partner in the field of implantology. With our end-to-end in-house manufacturing capabilities, we ensure precision, consistency, and absolute reliability – whether for customized one-offs or high-volume production.

Our core expertise lies in processing demanding materials such as titanium alloys, stainless steel and cobalt-chromium. We also offer supplementary services including deburring, blasting, anodizing and customized packaging solutions tailored to your product and market requirements.

We offer tailored solutions for your components, regardless of order size – whether for single parts, prototypes, or series production.

There’s no need to invest in expensive machinery or additional personnel. ARMBRUSTER handles the entire manufacturing process, allowing you to focus on your core competencies.

Our automation and efficient processes ensure rapid turnaround and on-time delivery of your orders.

We operate according to the highest standards and are certified to ISO 13485, the globally recognized quality management standard for medical devices.

Our automated production processes ensure efficient and seamless manufacturing that delivers top quality while optimizing costs.

With over 30 years of experience and a highly qualified team, we offer in-depth expertise and guarantee excellent results in every stage of the manufacturing process.

Our manufacturing is flexible, allowing us to respond quickly to changes and implement your requirements with precision at any time.

We offer a comprehensive selection of materials – from metals such as steel and aluminium to plastics – to ensure optimal manufacturing of your components.

With a standardized platform, we ensure system reliability, fast employee onboarding, and straightforward maintenance of our machines and equipment.

You have a dedicated contact who guides you through the entire process to implement your requirements efficiently and precisely.

Every implant is as unique as the patient it is designed for. Whether in joint replacement (hip, knee, shoulder) or in products for spine, trauma or bone reconstruction – we deliver precision-engineered solutions tailored to your needs.

Whether precision components for industrial use or custom implants for medical technology – we combine technical excellence with innovative solutions. With dedication and the utmost care, we create products that perform reliably in the most demanding situations.

| Industry: | Medical Technology |

| Application: | Titanium implant for metaphyseal bone replacement |

| Industry: | Medical Technology |

| Application: | Cobalt-chrome implant used as a shoulder prosthesis |

| Industry: | Medical Technology |

| Application: | Titanium implant (wedge) for foot bone fusion |

| Industry: | Medical Technology |

| Application: | Patient-specific bone replacement implant for the knee region |

| Industry: | Medical Technology |

| Application: | Housing for the electronics of a cardiac muscle stimulator |

| Industry: | Medical Technology |

| Application: | For stabilization and reconstruction of the foot bone |

| Industry: | Medical Technology |

| Application: | Titanium implant (wedge) for foot bone fusion |

| Industry: | Medical Technology |

| Application: | Housing for the electronics of a cardiac muscle stimulator |

| Industry: | Medical Technology |

| Application: | For stabilization and reconstruction of the foot bone |

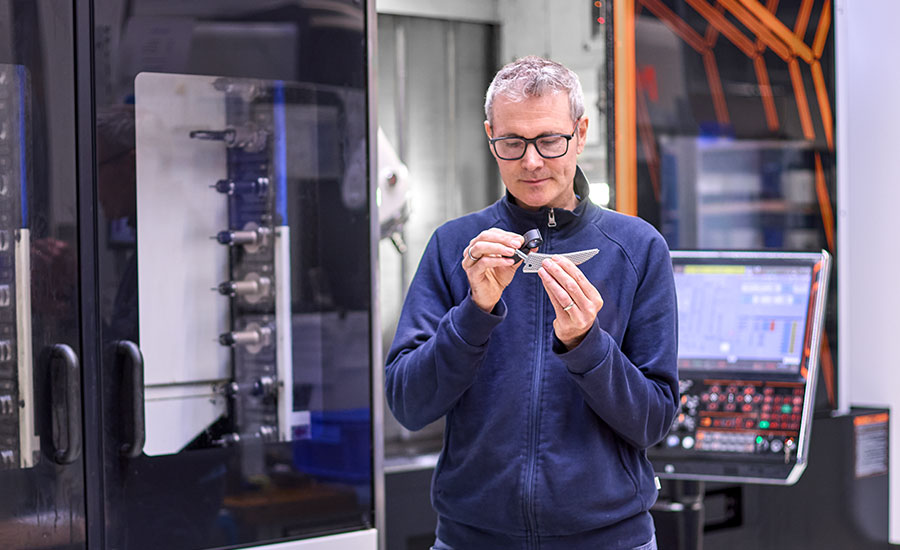

Our automated manufacturing processes and advanced machining centres ensure an efficient and seamless production workflow that delivers the highest quality while keeping costs optimized. Our state-of-the-art machinery is specifically designed for demanding production requirements and enables the precise manufacturing of high-quality implants:

For complex turned and milled parts with the highest precision requirements.

CAD-assisted machining of intricate geometries and multi-axis components.

For the precise machining of delicate components and challenging materials.

Fast and cost-efficient production of prototypes and functional parts using metal and plastic 3D printing.

In addition, we offer extensive surface finishing options – both in-house and in collaboration with a trusted partner network. This ensures seamless integration of post-processing steps such as anodising, blasting or surface refinement into the manufacturing process.

Do you have an inquiry or would you like to request a quote for contract manufacturing? Please use our inquiry form, where you can upload your order data and files (e.g. drawing) quickly and easily.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.

Because we offer more than just implant manufacturing – we build trust. With state-of-the-art CNC technology, decades of experience and a strong focus on quality, we set standards in medical technology. Our mission: perfection in every detail, backed by rigorous quality assurance and full compliance with all applicable regulations.

At ARMBRUSTER, we manufacture a wide range of implants that meet the highest medical standards. Our product portfolio includes:

Each product is manufactured individually for maximum precision and safety. With our expertise and precision, we help restore quality of life for patients around the world.

We specialize in machining titanium and cobalt-chromium alloys – materials known for their biocompatibility and high strength. We also process other medical-grade materials upon request. Contact us to discuss your specific needs.

Our expertise covers both machined and additively manufactured implants. Whether it’s single parts or small batch production, we develop tailored implant solutions to meet your project’s unique requirements.

Yes. We are experienced in serial production and regularly deliver implant batches in the thousands per year. We guarantee on-time delivery, consistent quality and a reliable partnership. Thanks to our automated machinery and optimized workflows, we can produce high volumes with precision and efficiency – making us your ideal contract manufacturer for both custom and serial implant production.

As a trusted contract manufacturer for medical devices, ARMBRUSTER delivers high-precision components that meet international quality standards. Our manufacturing portfolio includes:

Every product is manufactured with the highest precision and in compliance with the relevant regulations, supported by comprehensive quality assurance and traceability. We offer you tailored solutions for your specific requirements – from one-off production to series manufacturing.