As an experienced contract manufacturer in the field of machining, ARMBRUSTER offers outstanding solutions for metalworking and precision manufacturing. Whether it’s demanding individual components, complex assemblies or high-quality series production – our advanced machining technology is key to efficient and precise manufacturing. We rely on state-of-the-art CNC technologies, a fully equipped machine fleet, and a team of experts who place the highest value on quality and precision.

As an experienced partner in contract manufacturing for a wide range of industries, we ensure that every machining solution is implemented with precision, speed, and reliability. Our services include:

Using our state-of-the-art CNC machines, we manufacture turned parts from a wide variety of materials – from stainless steel to high-strength alloys – with precision that meets the highest standards.

We offer tailored solutions for a broad range of machining processes:

Our machining expertise includes CNC turning, CNC milling, and EDM (electrical discharge machining).

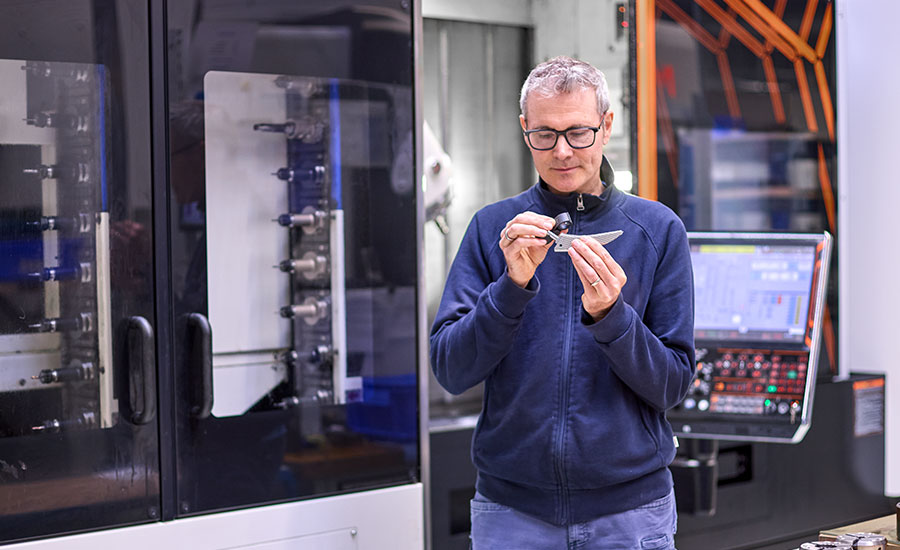

With our CNC machinery, we are at the forefront of state-of-the-art equipment in machining technology. Thanks to a wide range of advanced machines, ARMBRUSTER offers the flexibility needed for the production of small batches, large-scale series, as well as demanding one-off components.

The high capacity of our systems and full automation enable us to maintain a consistently productive and precise manufacturing process. Our philosophy: to combine as many machining steps as possible in a single run on one machine – ensuring the highest product quality and an optimized manufacturing flow.

Our process chain is fully integrated: Mechanically, we use a unified zero-point clamping system, allowing for fast and precise setup times. Digitally, intelligent software solutions support tool management and capacity planning. The result is seamless workflows that guarantee efficiency and quality at every stage of contract machining.

We offer tailored solutions for your components, regardless of order size – whether for single parts, prototypes, or series production.

There’s no need to invest in expensive machinery or additional personnel. ARMBRUSTER handles the entire manufacturing process, allowing you to focus on your core competencies.

Our automation and efficient processes ensure rapid turnaround and on-time delivery of your orders.

Our comprehensive quality control and the use of modern CNC machines ensure that all components are manufactured with the highest precision and tight tolerances.

Our automated production processes ensure efficient and seamless manufacturing that delivers top quality while optimizing costs.

With over 30 years of experience and a highly qualified team, we offer in-depth expertise and guarantee excellent results in every stage of the manufacturing process.

Our manufacturing is flexible, allowing us to respond quickly to changes and implement your requirements with precision at any time.

We offer a comprehensive selection of materials – from metals such as steel and aluminium to plastics – to ensure optimal manufacturing of your components.

With a standardized platform, we ensure system reliability, fast employee onboarding, and straightforward maintenance of our machines and equipment.

You have a dedicated contact who guides you through the entire process to implement your requirements efficiently and precisely.

Do you have an inquiry or would you like to request a quote for contract manufacturing? Please use our inquiry form, where you can upload your order data and files (e.g. drawing) quickly and easily.

With cutting-edge manufacturing technology and our expertise, we deliver custom-made products that impress with quality and reliability – always one step ahead.

At ARMBRUSTER, service is more than just a word – it’s our commitment to excellence. From the initial idea to perfect implementation and on-time delivery, we are at your side as partners with our many years of experience and state-of-the-art technologies.

Partnering with an experienced contract manufacturer ensures the highest manufacturing quality while giving you the freedom to focus on your core competencies – without the need to invest in costly machinery or additional personnel.

So why ARMBRUSTER?

At ARMBRUSTER, “contract manufacturing for machining” means more than just the precise processing of components. We focus on maximum efficiency and uncompromising quality – driven by advanced automation, in-depth process expertise, and a first-class CNC infrastructure. This enables us to guarantee consistently high-precision machining of your components, whether for individual parts, small batches or large-scale series.

Our CNC contract manufacturing stands for innovative processes: By intelligently integrating our wide range of technologies into a unified process chain, we achieve shorter lead times and increased efficiency – along with optimized capacity planning, end-to-end quality control and fast turnaround times. These advantages directly benefit your production. Our philosophy: Combine as many processing steps as possible on a single machine – to ensure optimal product quality, a smooth production flow, and fast, reliable delivery.

With our experienced team and flexible setup, we are a dependable contract machining partner that responds individually to your needs. Whether you require support with short-term projects or seek a long-term collaboration – ARMBRUSTER stands for quality, precision, and manufacturing that delivers on every detail.

Still not convinced? Feel free to get in touch – we’re happy to support you personally with your questions and requirements.

At ARMBRUSTER, we machine a broad range of materials – including steel, aluminium and plastics – precisely according to your specific requirements.

Whether it’s high-strength steels for medical applications, lightweight aluminium alloys for mechanical engineering, or specialized plastics – our modern machine park and technical expertise ensure precise, high-quality machining. This guarantees that every component meets the highest standards and performs reliably in its intended function.

Selecting the right material is crucial for the functionality and quality of the final product. As an experienced contract manufacturing partner, we are happy to advise you individually to help you choose the best solution for your requirements.

Yes – at ARMBRUSTER, we not only manufacture large-scale series, but also prototypes and small batch volumes. Our high level of flexibility and precise working methods enable us to produce even low-volume orders with maximum quality and efficiency. Whether you’re developing an initial prototype or require small quantities for specialized projects – we tailor the entire manufacturing process precisely to your individual requirements.

At ARMBRUSTER, “contract manufacturing for machining” means more than just precision manufacturing – it means delivering tailored solutions for a wide range of industries. Our machining technology is primarily used in medical technology and precision engineering.

In Medical Technology, we ensure the highest safety standards through validated and reproducible processes, full batch traceability, and risk-based quality control. Our extensive expertise in manufacturing surgical instruments and implants enables us to meet increasing regulatory requirements in the medical field – while maintaining flexibility, speed, and transparency. Notable services include prototype and series production of medical components such as hip and shoulder implants, knee prostheses, and specialized instruments for spinal and trauma surgery.

In the field of precision engineering, we supply complex parts for applications requiring the highest levels of accuracy and quality. Our customers particularly value our long-standing experience and our ability to deliver all services from a single source – including a wide range of surface finishes such as polishing, grinding, blasting, black oxide, copper plating, chrome plating, and gold plating.